January 19th, 2021

At Gannon University, construction is underway for I-HACK, Institute for Health and Cyber Knowledge. ‘I-HACK will serve as the global headquarters for academic, industry and business owners to design, integrate and protect cybernetic intelligence and data systems worldwide.’ [1] Originally scheduled to open in Fall 2020, the timeline has been extended until February 2021 due to the COVID-19 pandemic. The data center is approximately 12,000 sqft.

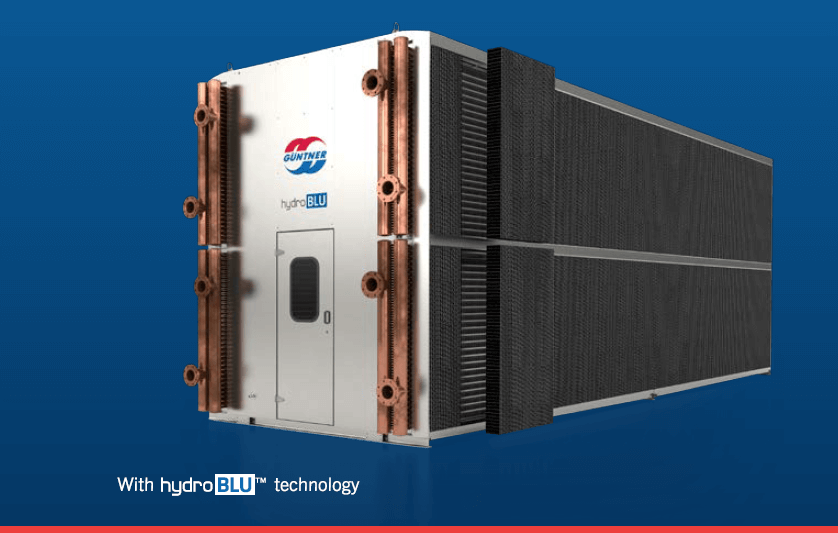

With the installation of the Guntner ADC HD (High Density) Dry Cooler, H&V Equipment Sales was able to eliminate issues of open towers, conserve water and allow the chiller to operate utilizing condenser water reset. Condenser water reset allows the chiller to have efficiencies as low as 0.1 kw per ton when the condenser water is four degrees above the chilled water temperature. The Adiabatic Dry Cooler / High Density was designed to have maximum power and efficiency within a minimal footprint.

Explore the campus further by visiting the virtual tour.

Reference: [1] Gannon University I-HACK Institute for Health and Cyber Knowledge

January 20th, 2015

The PMI-IF-H series are indirect fired make-up air units that utilize premier 90% efficient stainless steel convoluted tube heat exchangers. The new 90% furnace is capable of reducing operating costs by up to 11% as well as reducing C02 emissions. By separating combustion air from the supply air, the unit is able to maintain excellent indoor air quality (IAQ). These efficient gas heat units can be used in schools, offices, and institutional projects – anywhere that IAQ is paramount.

Follow the link to learn more.

http://www.priceindustries.com/products/details/permlink/423